RICON TrackBin®

Overview

RICON Intelligent Trash Bin

Remote Monitoring & Management Solution

RICON TrackBin® Solution has been developed specifically for the trash collection sector.It is dedicated for companies/administration units that wish to increase effectiveness and control of trash collection process as well as rationalize its costs.

Solution provides:

Trash bin fill and temperature level remote monitoring

In-time trash collection from various locations,

Substantial cost savings (lower fuel cost, lower labor cost),

Data storage for statistics and trend analyses,

Helps to keep the environment clean.

RICON TrackBin® Solutions consists of:

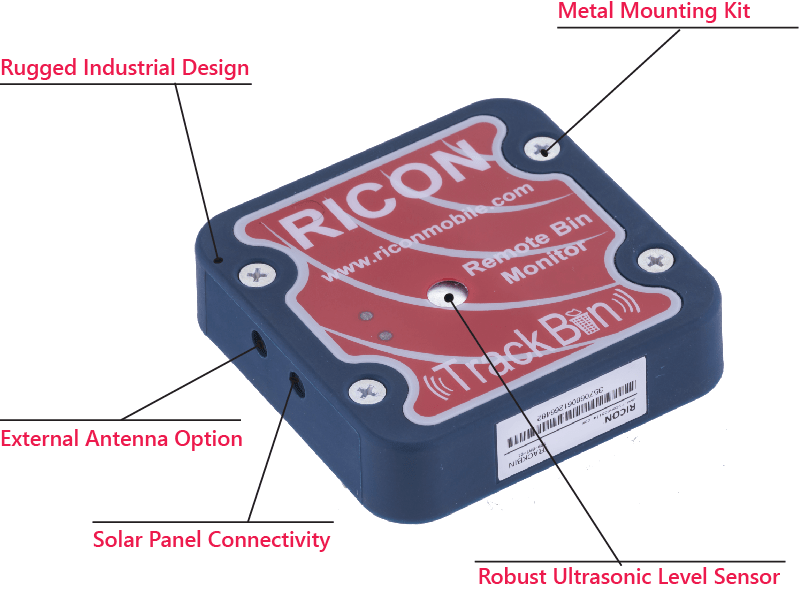

TrackBin® Device (with ultrasonic sensor for accurate non-contact trash level monitoring; temperature sensor for measuring temperature level inside the trash bin)

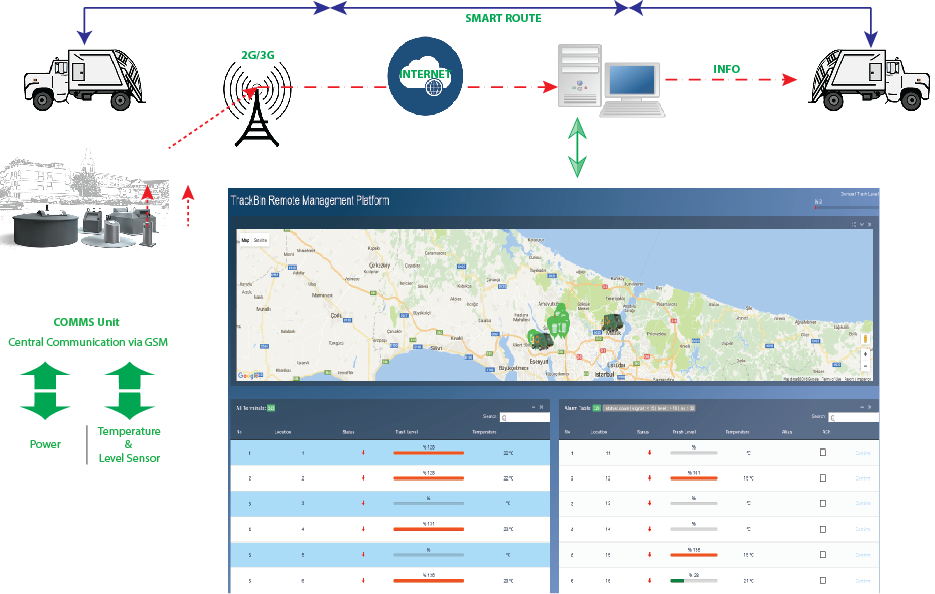

TrackBin® Communication System for transferring collected data over mobile network to the management center

TrackBin® Management Software with user web interface platform

How does it work:

The garbage level and cabin temperature are measured by the device in 2-5 minutes intervals.

In case of a garbage level or a change in temperature level, the measured values are transferred to the central control server via the GPRS network.

The data to the central control server is written to a database on that server.

The data in the database is interpreted by the TrackBin Management System and delivered to the user via a web interface.

In this way, garbage level can be directed to the garbage level rising positions and the garbage level and temperature levels in the locations can be analyzed and necessary measures can be taken.

What is the TrackBin® Management System?

Provides monitoring of all containers defined in the system. In the TrackBin® Management System, the user can view the garbage levels of the containers, the temperature values in the cabin and report and analyze them depending on these values. In the light of this data, only garbage can be transported to the elevated positions, thus saving fuel and time. At the same time, alarms are generated at predetermined threshold values depending on both the garbage level and the cabin temperature. In these cases, the garbage containers, which are prematurely filled early, or the containers that are likely to fire are also intervened early.

Container List

All containers are displayed in the Container List here. Users can access the following information:

Existing container status (online, offline): Indicates whether the container is sending data. This allows you to monitor the operation of the device on the screen.

The latest data from containers (signal strength, garbage level, temperature inside the cabinet, battery status): Shows the last time data was received from the container and the incoming data.

Container Location: Shows geo-code where the container is located.

In addition, referring to the Terminal Detail page where the user can examine the details of each terminal is done on this page.

Different levels of garbage and temperature levels are represented by different colors for easy monitoring.

It can be searched by IMEI, Location and Group, and all search results and reports can be transferred to an excel worksheet in one click.

The unwanted terminal can be removed from the system.

System and Security Settings

Authorization List

The Authorization List shows the containers that want to connect to the system. Containers are automatically brought to the Authorization List due to security measures and cannot be connected to the system unless the user agrees.

In the Authorization List, the user can:

• Accepting the incoming container; With this process, the container is included in the system and can be monitored.

• Reject the incoming container; The container is listed in the Black List and the data from that container is no longer considered.

Black list

Shows Blacklisted containers. The user can remove the selected container from the list.

Groups

In order to monitor the containers in the system easily, Group is created and a container is assigned to these groups. For example, a group can be created and monitored under a group for containers of the same location. This will prevent confusion. In addition, created groups can be deleted, group defined containers can be added and removed.

TrackBin® Battery Type

The battery-operated Trackbin has the same features as the Trackbin, powered by electricity. The only difference is that when the battery is used, the device generates an occupancy alarm only when certain occupancy rates are reached. This is due to prolonging the service life of the used batteries and avoiding operational battery replacement costs. The Trackbin device will continue to operate for at least 1, maximum 2.5 years in normal environmental and weather conditions. The battery level is reported in the central management system. When the battery has reached the end of its life, the device is opened and the battery is replaced and the device will continue to work by replacing it.

Quick Specifications

Live Fill Level Monitoring

Temperature Monitoring

Trash Collection Alarms

Device Status & Health

Statistical Trend Analysis

Substantial Cost Saving

Reduced Labor & Fuel Costs

Autonomous Industrial Design

Mobile Monitoring For Vehicles

Vehicles Global Positioning

System (GPS)

Specifications

PROBLEM OVERVIEW |

The main problems of the existing trash collection process are :

Due to growing population, urbanization and increasing consumption more attention is put into the trash management. |

SMART PLATFORM FEATURES | |

Easy Monitoring |

|

Customizable Data Flow |

|

Intelligent Features |

|

FUNCTIONAL FEATURES | |

Hardware Includes : |

|

Software Includes : |

|

Topology

Downloads