In the paint industry, both globally and in Turkey, there has been a longstanding trend of "producing zero-color paint, with all coloring done at the point of sale." The use of paint coloring systems for production and marketing has become a dominant business model in our country, as well as in many other countries.

The use of color machines by distributors is becoming increasingly common. In cases where the system cannot be monitored live in terms of faults, maintenance, and operations, they may lose their competitive edge against rivals and fail to achieve the expected benefits from their investments.

The updating of paint codes and prices in color machines is generally done manually through on-site service by paint companies. This process is not only costly in terms of human resources and time but can also lead to delays in responding to customer demands, potentially resulting in lost market share and customers.

When color machines are accessible online;

- The necessary paint color codes, machine settings, and prices can be updated instantly from a central location.

- When updates are needed, the time and cost associated with physically sending personnel to the field are completely eliminated.

- The usage frequencies of paint color machines and their operational statuses can be monitored in real time. The performance related to the distributor's use and maintenance of the color machine can be assessed without delay, allowing for prompt interventions when necessary.

- For online operation, access issues arising from the use of the distributors' local lines (such as internet outages, password changes, IP changes, local line failures, etc.) are eliminated.

- Online access is provided through a secure connection exclusively between the color machine and the manufacturer's central system.

- Through the online system, color machines can also be controlled remotely, their software can be updated, and adjustments can be made to their settings.

- The inventory of paint machines is also automatically maintained, ensuring awareness of situations such as relocations.

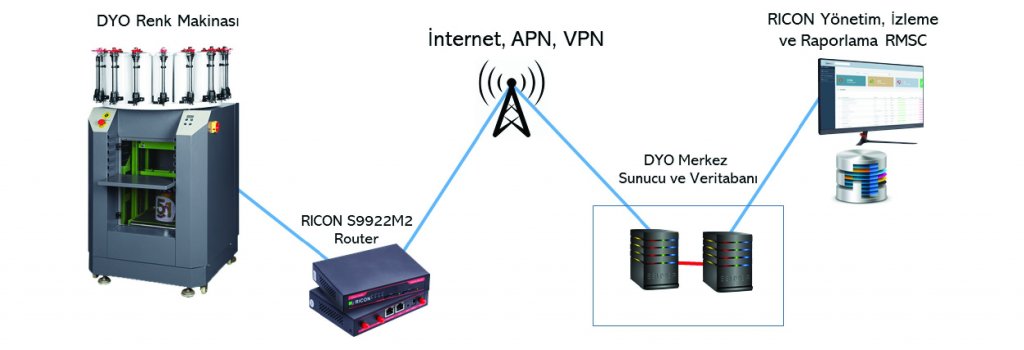

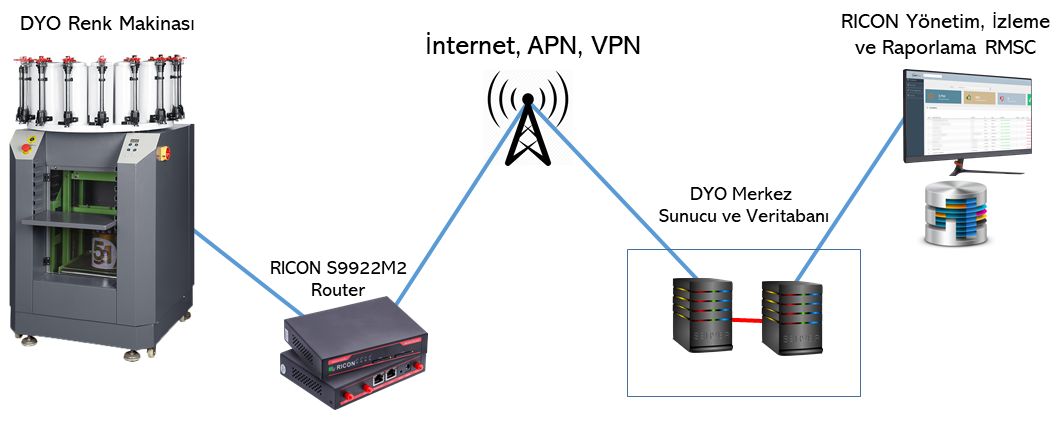

To achieve the aforementioned benefits, Ricon Router products, produced as 100% Turkish goods, facilitate fast and secure online data communication for the centralized management of color machines by accommodating one or two SIM cards. As Ricon, our products are used in paint machine automation across 20 countries worldwide.

Ricon products are managed through a centralized management system, RMSC, which offers a single operational interface. Additionally, the central software program enables automatic installation and updates, allowing customers to view the current list of color machines and distributors in the field, along with the machine inventory, all on a single screen.

Our company has been engaged in research and development activities for 20 years. The Ricon Mobile Access devices produced are in operation in various retail chains across different sectors, including paint manufacturers, with over 80,000 units currently in use. Additionally, more than 350,000 Ricon devices are being utilized in Europe and America.

Polaris Plaza Kat: 6 Ahi Evran Cad. No: 21, Maslak Istanbul

0212-3462600